Silicon carbide ceramics and silicon carbide are two different materials. Although they both contain silicon carbide, there are significant differences in preparation methods and application fields.

First of all, silicon carbide ceramic is a ceramic material prepared from silicon carbide powder. Its preparation process usually involves mixing silicon carbide powder with some kind of organic binder, and then shaping it through the process of pressing and sintering. Silicon carbide ceramics have extremely high hardness, wear resistance and high temperature resistance, and are usually widely used in mechanical engineering, chemical industry, energy and other fields. Due to its good corrosion resistance and thermal conductivity, silicon carbide ceramics are also used as high-temperature furnaces, refractory materials, and substrates for electronic devices.

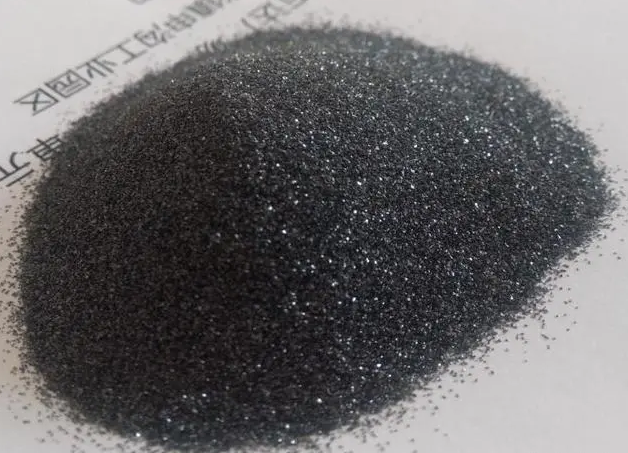

In contrast, silicon carbide is the name of a chemical substance with the formula SiC. It can be obtained by reacting silicon and carbon at high temperature. Silicon carbide has a very high melting point and hardness, so it is widely used in the fields of refractory materials, abrasives and grinding tools. Silicon carbide's high melting point and chemical stability enable it to operate stably at high temperatures for a long time, so it is used as a material for furnaces and as a carrier for high-temperature reactors and catalysts.

Although silicon carbide ceramics and silicon carbide are different in preparation methods and application fields, they have some common characteristics. First of all, they all have excellent high temperature resistance and can operate stably for a long time in extreme environments. Second, they are both very hard and effectively resist wear and corrosion. In addition, both silicon carbide ceramics and silicon carbide have a low thermal expansion coefficient and excellent thermal conductivity, making them excellent in high temperature, high pressure and high speed environments.

To sum up, although silicon carbide ceramics and silicon carbide both contain silicon carbide, there are significant differences in preparation methods and application fields. Silicon carbide ceramics are mainly prepared by mixing silicon carbide powder and organic binders, and are widely used in mechanical engineering, chemical and energy fields. Silicon carbide is the name of a chemical substance with a high melting point and excellent fire and corrosion resistance, and is widely used in the fields of refractory materials, abrasives and grinding tools.