Reaction sintered silicon carbide (RBSIC) is a ceramic material that is produced by combining silicon carbide powder with a small amount of binder and then sintering it at high temperatures. It has excellent mechanical properties, high thermal conductivity, and good chemical resistance. This article will discuss the important technical parameters of reaction sintered silicon carbide.

1. Density:

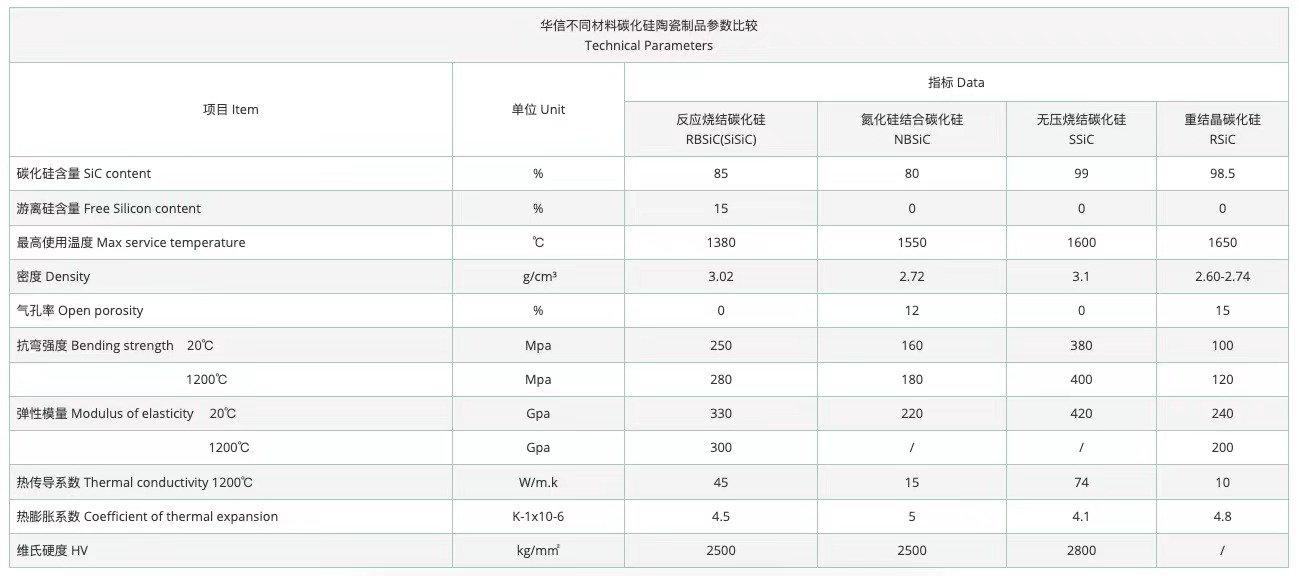

The density of reaction sintered silicon carbide is an important parameter that determines its strength and stability. It is typically in the range of 3.00 to 3.20 g/cm³. The high density ensures that the material is highly compact and has minimal porosity, resulting in improved mechanical properties.

2. Hardness:

Reaction sintered silicon carbide is known for its exceptional hardness. It has a hardness value of around 2300-2800 kg/mm² on the Vickers scale. This high hardness makes it suitable for applications requiring wear resistance, such as cutting tools, nozzles, and bearings.

3. Flexural Strength:

The flexural strength of reaction sintered silicon carbide is another crucial parameter. It measures the material's ability to withstand bending without breaking. RBSIC typically exhibits a flexural strength of 350-450 MPa, which is higher than most other ceramics. This high strength allows for its use in demanding structural applications.

4. Thermal Conductivity:

Reaction sintered silicon carbide possesses excellent thermal conductivity, making it suitable for applications involving high temperatures. Its thermal conductivity ranges from 120 to 200 W/m·K, depending on the specific composition and processing conditions. This property enables efficient heat dissipation and thermal management in various industries.

5. Chemical Resistance:

RBSIC has good resistance to a wide range of chemicals, including acids, alkalis, and molten metals. This makes it an ideal material for use in aggressive environments where corrosion resistance is essential. Its chemical resistance also ensures long-term durability and reliability in harsh operating conditions.

Conclusion:

Reaction sintered silicon carbide offers numerous advantages due to its unique combination of mechanical, thermal, and chemical properties. The technical parameters discussed above, including density, hardness, flexural strength, thermal conductivity, and chemical resistance, highlight its suitability for various industrial applications. Whether it is used in cutting tools, heat exchangers, or wear-resistant components, RBSIC proves to be a reliable and efficient material choice.