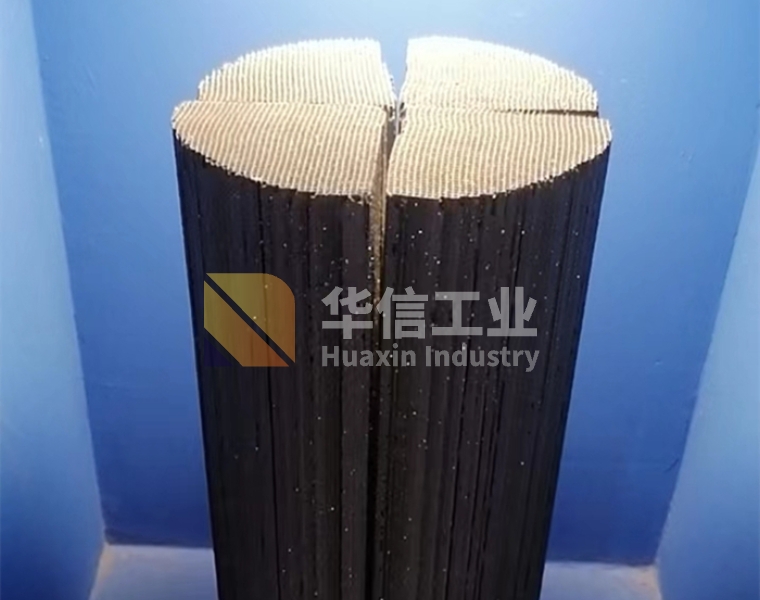

Silicon carbide particulate filters

Recrystallized silicon carbide honeycomb ceramic wall flow particle catchers (DPF), is an important part of diesel vehicle exhaust purification device, used to eliminate harmful substances in diesel vehicle exhaust, the principle is to use silicon carbide high temperature resistance characteristics, made into honeycomb ceramic carrier, coated with precious metals and rare earth elements made of composite catalyst. By using the porous thin walls between the interlocking cellular channels, the ultra-fine particles of harmful components such as PM, CO and HC in the exhaust gas of diesel vehicles are captured, and then the emission standards stipulated by the national regulations are achieved through the principle of catalytic combustion. DPF can effectively purify 70%-90% of the particles in the exhaust, which is one of the most effective and direct methods to purify diesel particulate matter, and has been commercialized internationally.

- Typical application

- Features and advantages

- Specification

-

Typical application

Recrystallized silicon carbide honeycomb ceramic wall flow particle catcher (DPF) is an important part of diesel vehicle exhaust purification device, which is used to eliminate harmful substances in diesel vehicle exhaust.

-

Features and advantages

Silicon carbide DPF has the following characteristics and performance indicators:

1. Excellent high temperature resistance;

2. Excellent corrosion resistance;

3. Good thermal conductivity;

4. Good thermal shock stability;

5. High carbon load;

6. Small exhaust resistance;

7. Strong pressure resistance, high mechanical strength;

8. Long service life;

9. High filtration effect of carbon smoke particles -

Specification

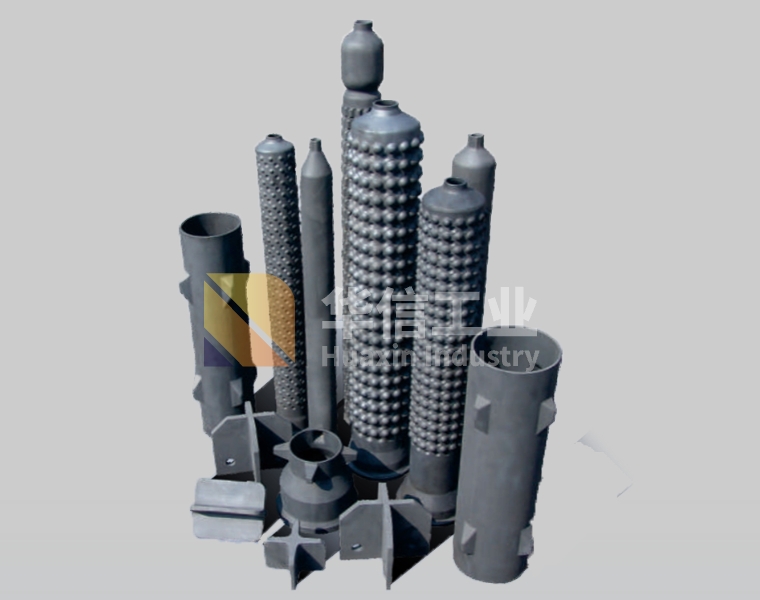

Related Products