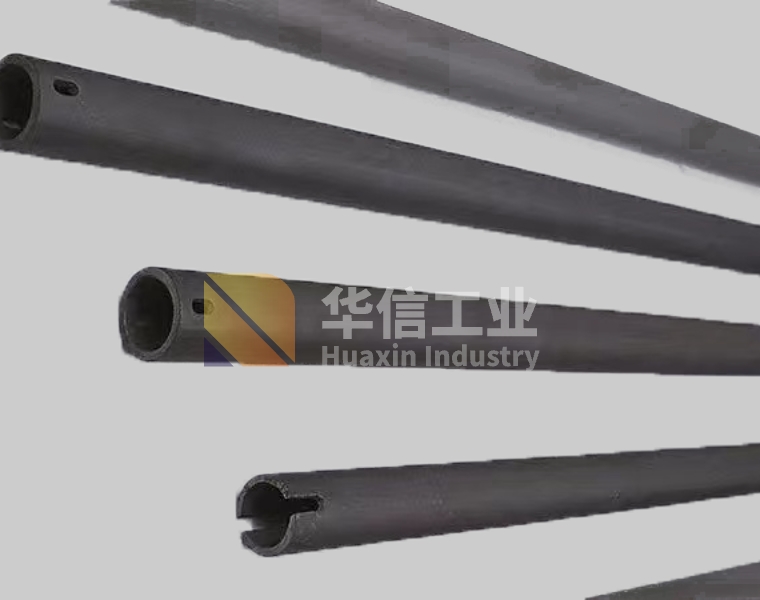

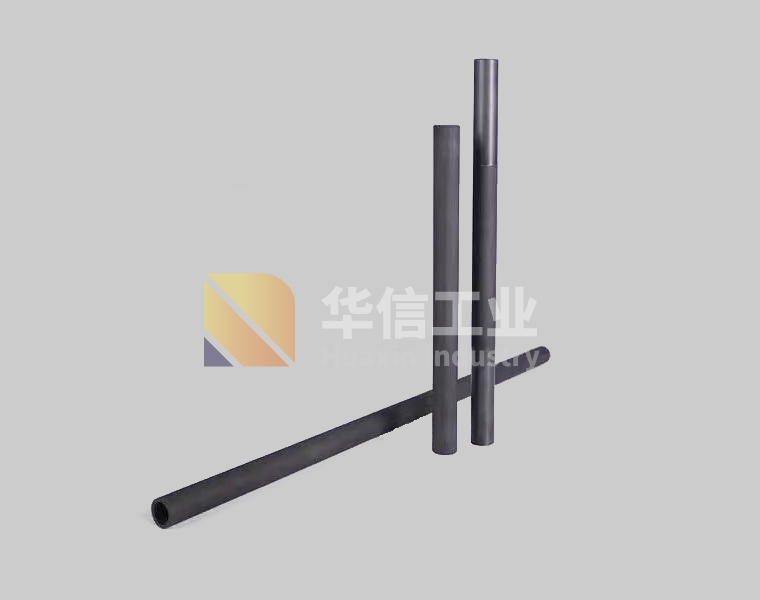

Kiln tubes

Silicon carbide kiln tubes are usually formed by isostatic pressing. Through our manufacturing expertise, we are able to produce kiln tubes with extremely tight tolerances. Add flanges, drilling holes, cutting grooves, etc.

- Typical application

- Features and advantages

- Specification

-

Typical application

The kiln tubes is heated externally and provides the required working environment internally

Furnace tube for kiln

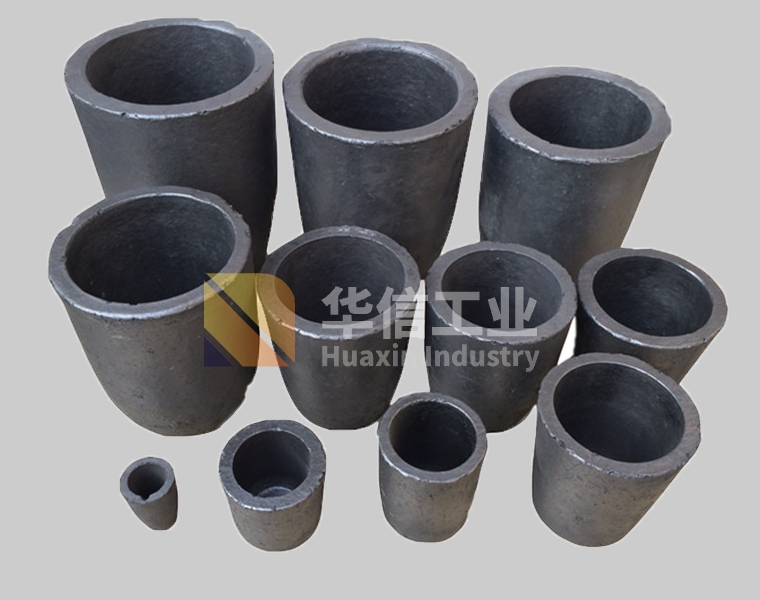

Kiln furniture

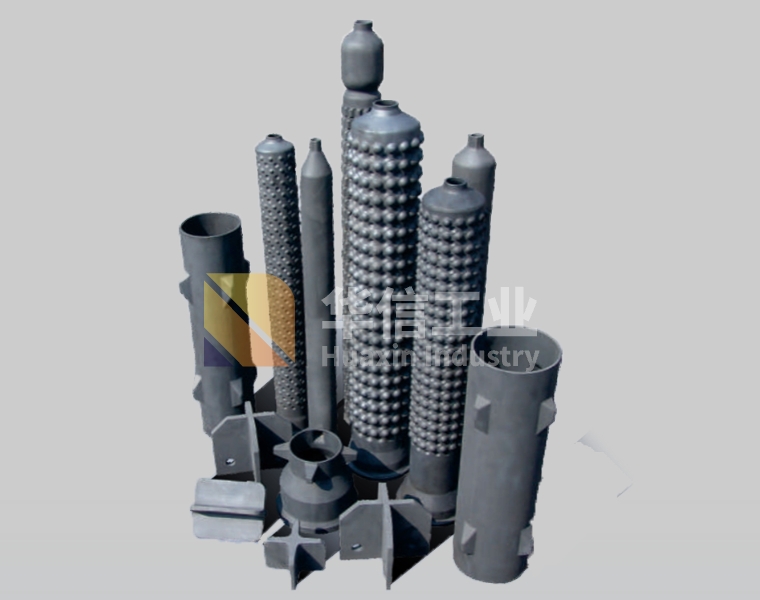

Vacuum furnace components

Suitable for the lining of high temperature, ultra-high temperature electric furnace and kiln above 1400℃ is especially suitable for high-corrosive high-temperature tubular heating furnace, sintering furnace, reactor and other heating furnace lining -

Features and advantages

Silicon carbide kiln tubes, with good thermal stability, can be used up to 1700 degrees Celsius (air atmosphere), or 1950 degrees Celsius (nitrogen or argon atmosphere) - high temperature resistance

The kiln tubes has good density, from room temperature to 1000℃, gas impermeability to 31MPa, to meet the requirements of vacuum - high pressure resistance

silicon carbide has a high purity, silicon carbide content greater than 99%, will not pollute the material.

Ilicon Carbide kiln tubes offer excellent corrosion and wear resistance, even at high temperatures, without contaminating materials.

Thanks to high thermal conductivity and good thermal shock properties, silicon carbide kiln tubes are adapted to rapid changes in temperature - excellent thermal shock resistance -

Specification

silicon Carbide furnace tubes are usually customized products according to customer requirements

The outer diameter is up to 350mm and the length is up to 2000mm.

Larger sizes of furnace tubes can be made by ceramic welding

Related Products