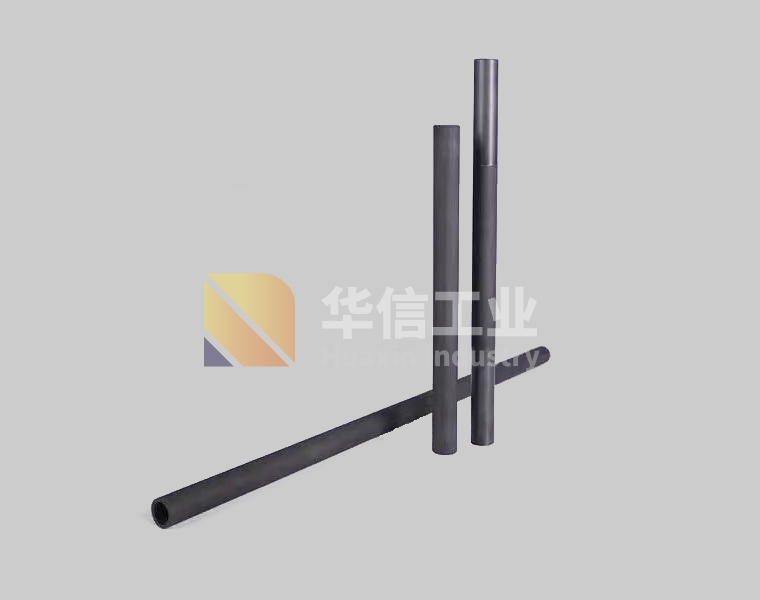

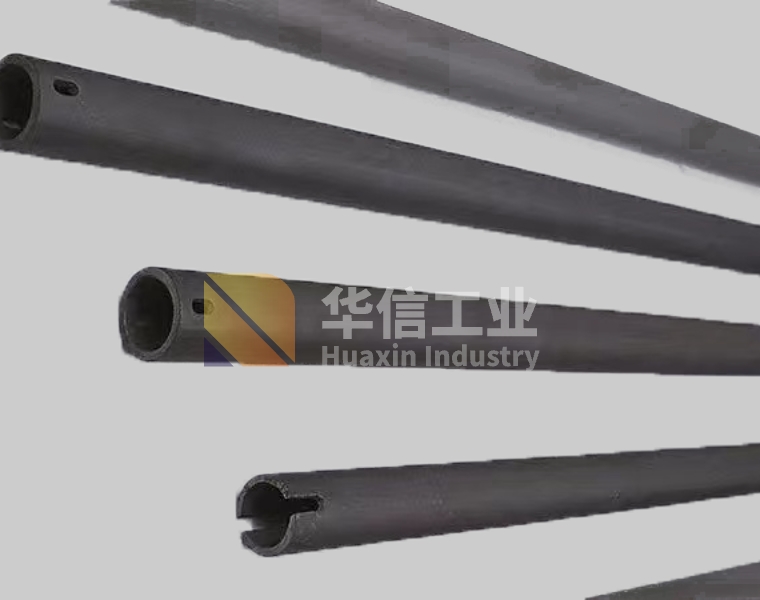

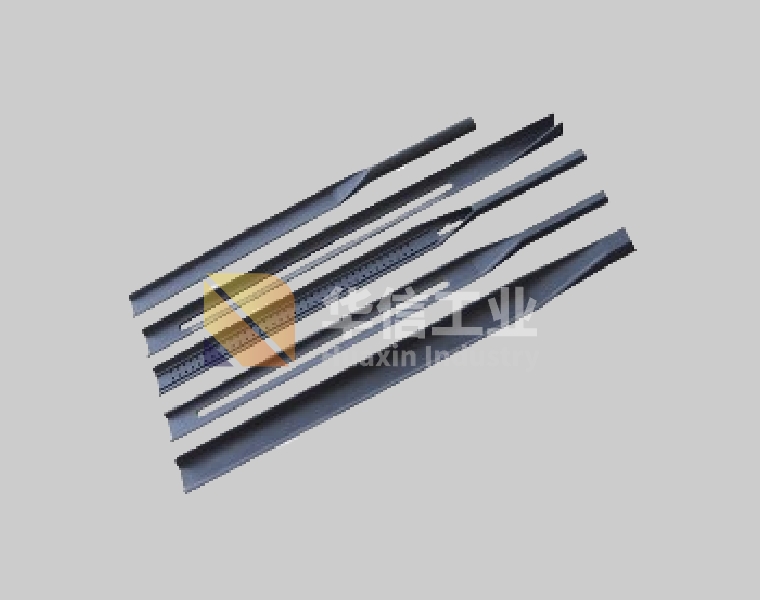

Cantilesvers paddles

Reaction-sintered silicon carbide cantilever propeller is a key component of semiconductor wafer loading system.

- Typical application

- Features and advantages

- Specification

-

Typical application

The cantilever paste has stable performance, does not deform in high temperature environment, and has large wafer loading capacity, which is suitable for robot automatic devices and handling systems.

Monocrystalline silicon and polysilicon coating diffusion furnaces for photovoltaic industry.Used to send a silicon boat or quartz boat containing silicon wafers into the tube of a coating diffusion furnace.

-

Features and advantages

The cantilever propeller has stable performance, no deformation in high temperature environment, and large wafer loading capacity, which is suitable for robot automatic loading and handling systems.

Due to the stable and undeformed section of the cantilever propeller, it is possible to prepare larger wafers using existing furnace tubes.

The cantilever paddle has a similar thermal expansion coefficient to the LPCVD coating, which is applied to the LPCVD, greatly extending the maintenance cleaning cycle and significantly reducing contaminants. -

Specification

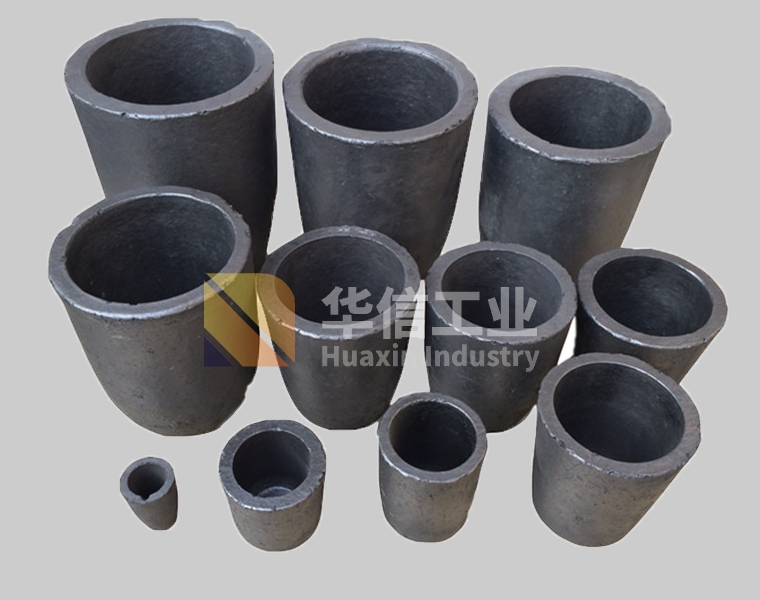

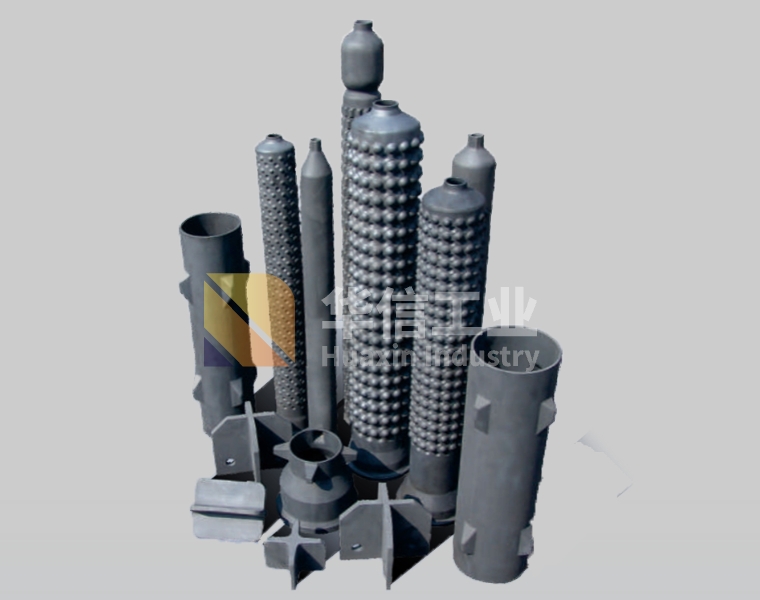

Related Products