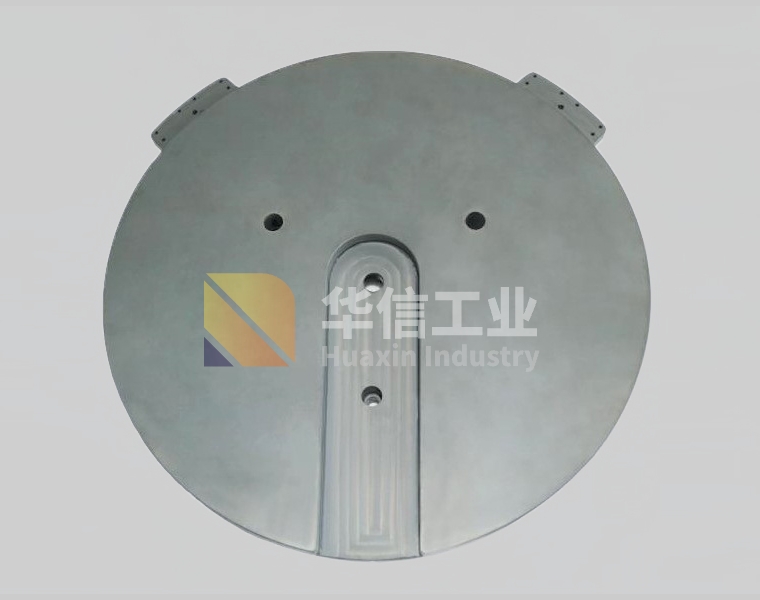

Vacuum sucker

Silicon carbide vacuum sucker was formed by isostatic pressing process and sintered at high temperature. According to the requirements of the user's design drawings, the outline size, thickness size and shape can be refined to meet the specific requirements of users.

- Typical application

- Features and advantages

- Specification

-

Typical application

In semiconductor manufacturing, an extremely thin wafer is placed on a silicon carbide vacuum sucker, connected to a vacuum generator, and the vacuum suction is used to hold the wafer in place.

It can be used in optical engraving, etching, laser processing, wafer inspection and other processes.

-

Features and advantages

Precise dimensions and thermal stability .

Good thermal conductivity, low expansion coefficient and temperature equalization performance .

High wear resistance and surface finish, small pore size and uniform distribution, uniform adsorption of all regions of the wafer .

Excellent acid and alkali corrosion resistance .

Resistance to plasma impact. -

Specification

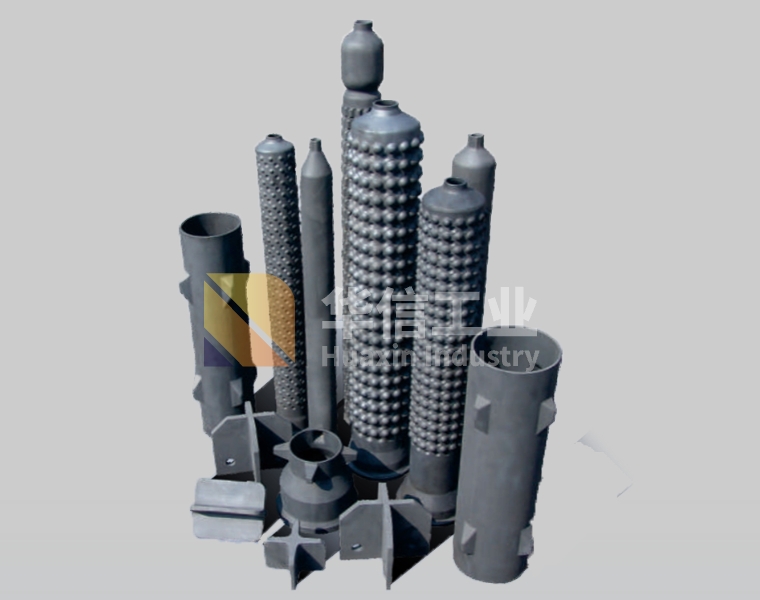

Related Products