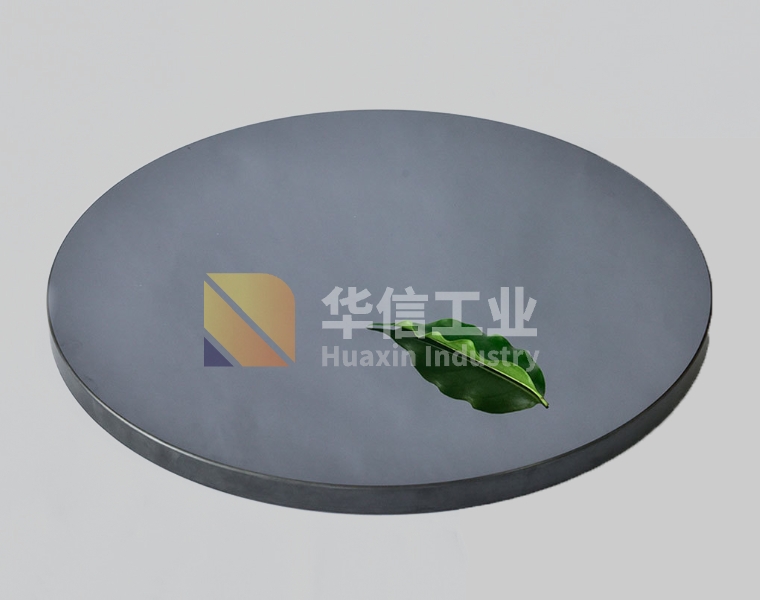

CMP carrier disk

The silicon carbide CMP carrier plate was formed by isostatic pressing process and sintered at high temperature. According to the requirements of the user's design drawings, the outer diameter, thickness, the number and size of acupuncture points, the position and shape of the slot can be refined to meet the specific requirements of the user

- Typical application

- Features and advantages

- Specification

-

Typical application

CMP in LED chip manufacturing, that is, chemical mechanical polishing process.

-

Features and advantages

Good thermal conductivity, low expansion coefficient and temperature equalization performance.

Compared with the traditional corundum plate, shorten the heating and cooling time of loading and unloading, improve the working efficiency; At the same time, it can reduce the wear between the upper and lower plates, maintain good plane accuracy, and extend the service life of about 40%.

The material proportion is small, the weight is light, the operator is easier to move the carrying tray, and the risk of collision damage caused by handling difficulties is reduced by about 20%.

-

Specification

Can be processed according to customer drawings, the maximum size: 500mm diameter, flatness: 0.003mm or less.

Related Products