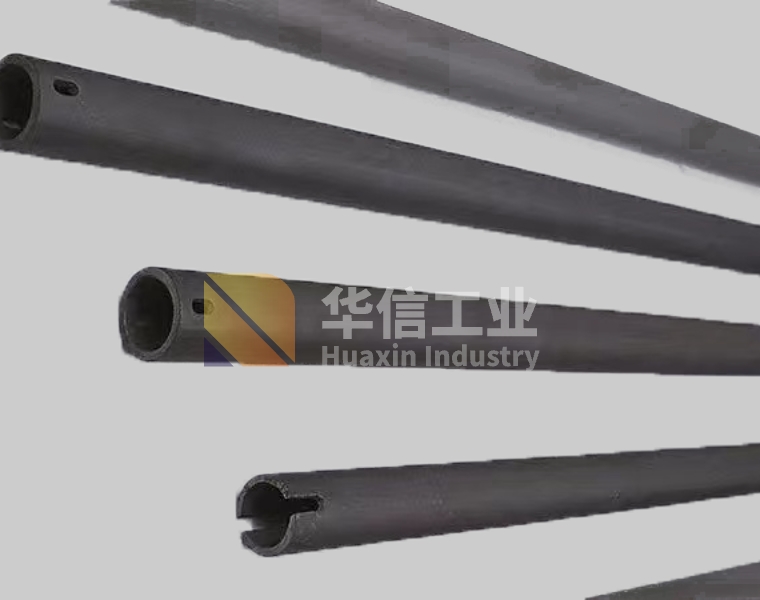

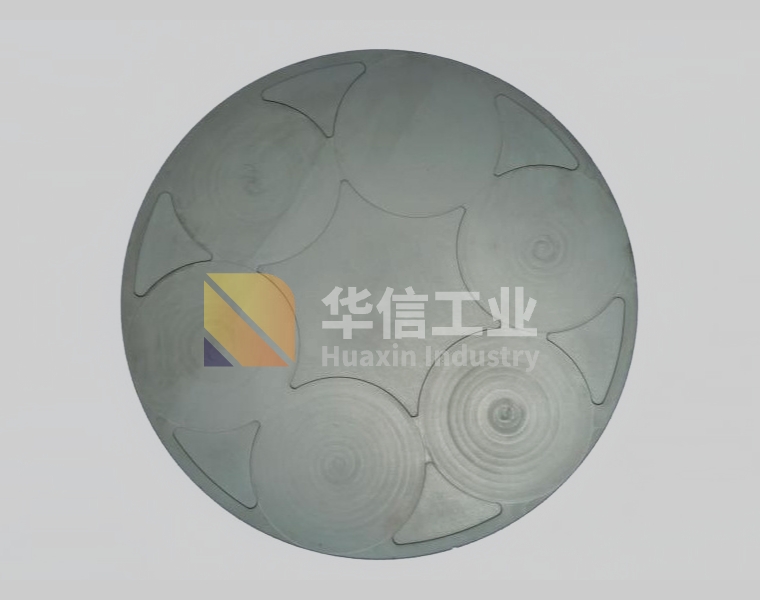

PVD carrier

The silicon carbide PVD carrier plate was formed by isostatic pressing process and sintered at high temperature. According to the requirements of the user's design drawings, the outer diameter, thickness, the number and size of acupuncture points, the position and shape of the slot can be refined to meet the specific requirements of the user

- Typical application

- Features and advantages

- Specification

-

Typical application

PVD process in LED chip manufacturing, that is, physical vapor deposition.

-

Features and advantages

High density

Good thermal conductivity, low expansion coefficient and temperature equalization performance

Resistance to plasma impact

Resistant to various strong acid and alkali chemical reagents

After semiconductor grade cleaning -

Specification

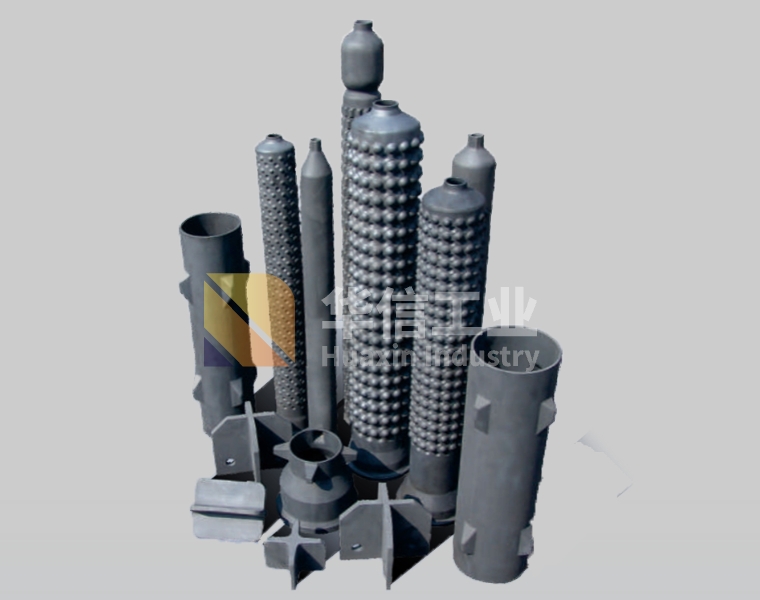

Related Products