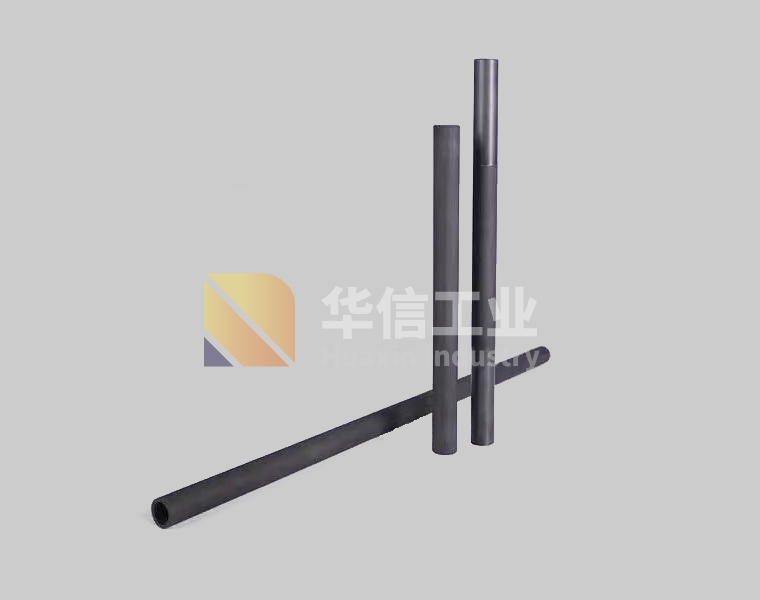

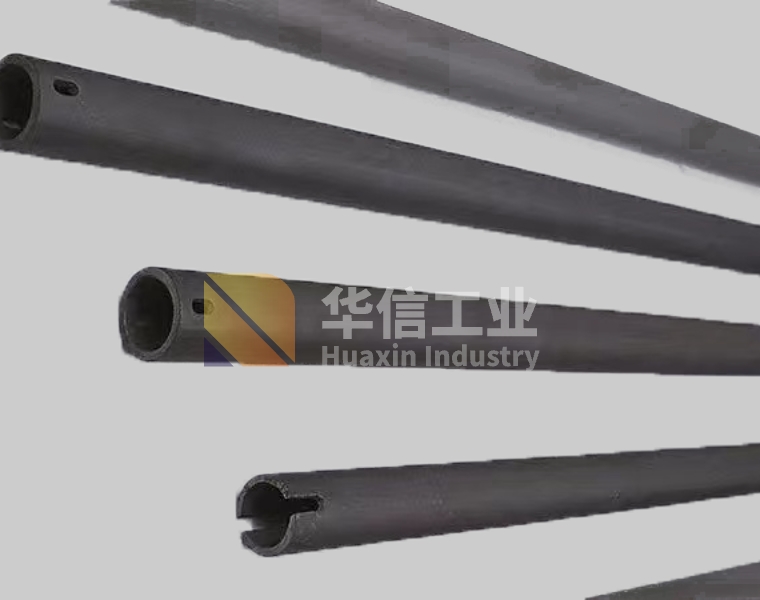

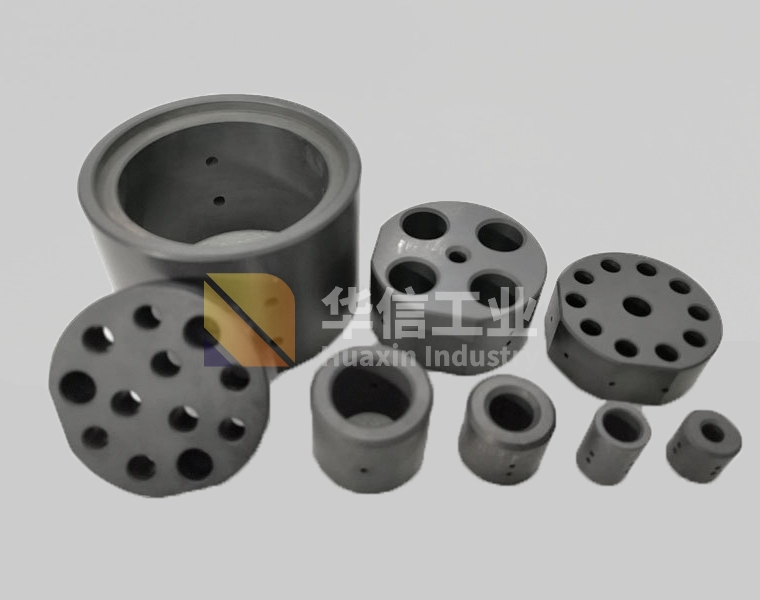

Die sleeve

Silicon carbide mold sleeve is made of isostatic pressing and high temperature sintering. The inner circle process hole and exhaust hole can be processed according to the user's design requirements to achieve the specified precision tolerance.

- Typical application

- Features and advantages

- Specification

-

Typical application

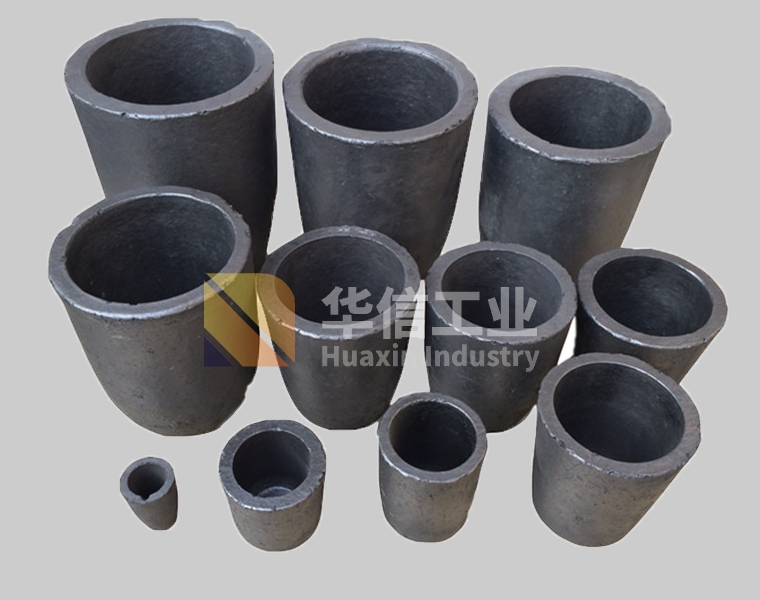

Aspherical glass thermoforming die (sleeve)

-

Features and advantages

It still has high hardness and mechanical strength at high temperature to avoid surface scratching during the molding process;

Excellent surface processing quality, no porosity on the surface, smooth optical mirror, no adhesion to the glass, good demoulding performance;

Excellent oxidation resistance under high temperature environmental conditions, high temperature will not react with optical glass, stable surface quality;

High thermal conductivity, low thermal expansion, heat shock performance: withstand repeated heating - cooling and other thermal cycles in the molding process, long life;

Because the thermal expansion coefficient of silicon carbide is slightly lower than that of tungsten steel, the match with tungsten steel die is very suitable, it is more convenient to take and put the die, and the life of the die can greatly reduce the product cost -

Specification

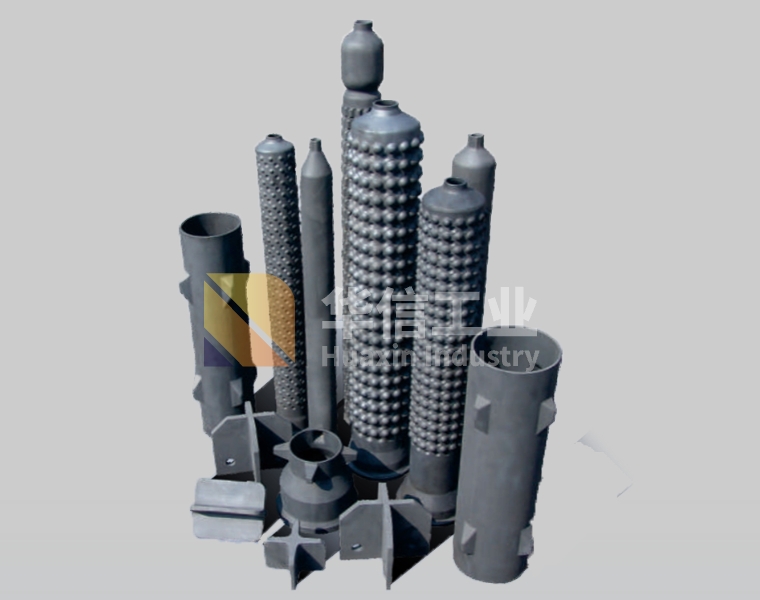

Related Products