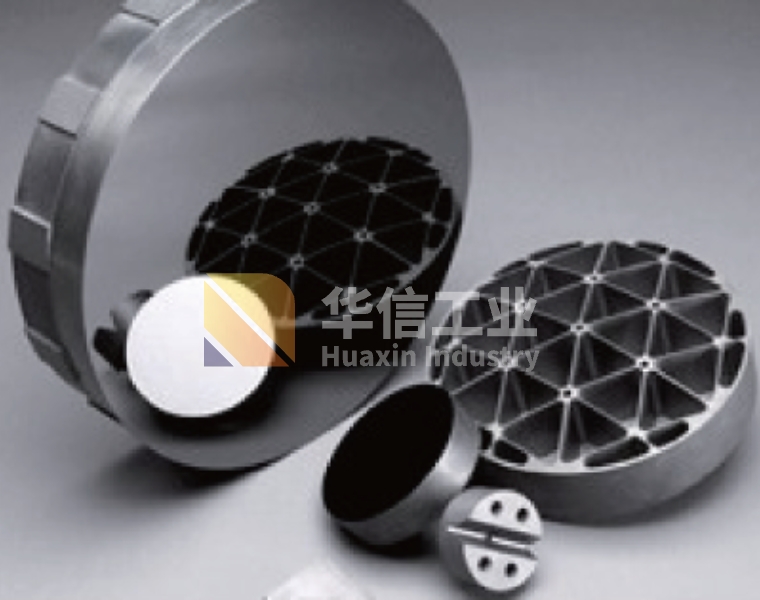

Reflector

SiC ceramic material is the main space mirror material, widely used in aviation, aerospace scanning mirror, mirror, optical system and so on.

The thermal conductivity of silicon carbide is very high, which is nearly 100 times that of traditional glass materials.

Compared with traditional glass materials, heat transfer in silicon carbide has a faster speed.

Therefore, the use of silicon carbide material to prepare the mirror, can minimize the temperature gradient on the mirror, when the ambient temperature changes, the entire mirror body temperature can quickly reach the same.

Internationally commonly used mirror matrix materials are quartz glass, glass-ceramics, silicon carbide, beryllium metal, and carbon fiber/silicon carbide composite materials.

Compared with other materials, silicon carbide has greater specific stiffness and thermal stability, which means that when achieving the same optical aperture and accuracy requirements, silicon carbide mirrors have less weight and better thermal stability, so silicon carbide has become a leader in large aperture mirror blank materials.

- Typical application

- Features and advantages

- Specification

-

Typical application

SiC ceramic material is the main space mirror material, widely used in aviation, aerospace scanning mirror, mirror, optical system and so on.

-

Features and advantages

Compared with other materials, silicon carbide has greater specific stiffness and thermal stability, which means that when achieving the same optical aperture and accuracy requirements, silicon carbide mirrors have less weight and better thermal stability, so silicon carbide has become a leader in large aperture mirror blank materials.

-

Specification

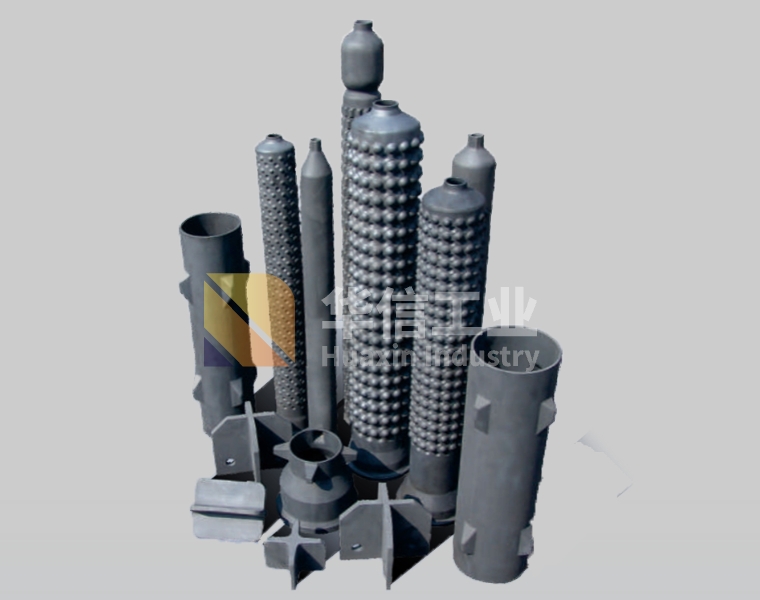

Related Products