Single

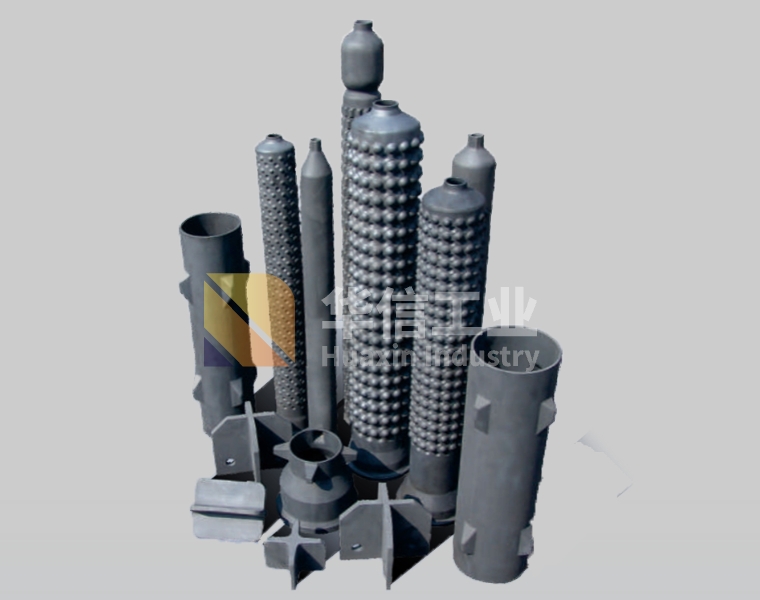

The silicon carbide vortex nozzle is the slurry enters the vortex room of the nozzle from the tangential direction, and then ejects from the spray hole at a right Angle to the entrance direction, the whole grouting molding, no internal separation parts, the spray shape is hollow conical, the spray area is in a ring, a variety of spray angles and flow rates, the spray shape is conical, the spray area is in a ring, the spray particle size of the vortex nozzle is small and uniform, and the spray size is small and uniform.

The vortex channel is large, and the nozzle is not easy to plug.

The high pressure pump is used to make the slurry obtain higher pressure and enter the rotation chamber of the nozzle from the tangential entrance. The slurry obtains rotational motion in the rotation chamber. According to the principle of conservation of rotational momentum, the slurry accelerates rotation to form a circular film around the rotation.

The serous film elongates and thinens, and finally splits into small droplets and forms a cone serous fog.

- Typical application

- Features and advantages

- Specification

-

Typical application

-

Features and advantages

-

Specification

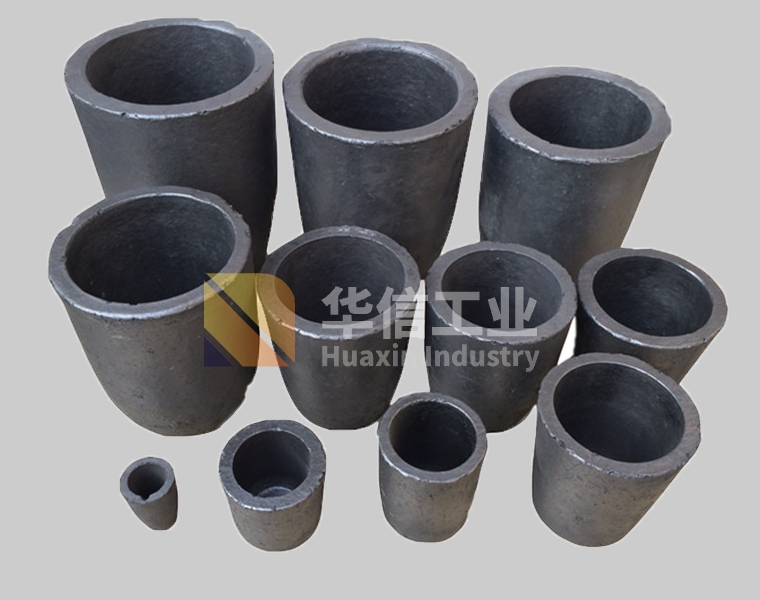

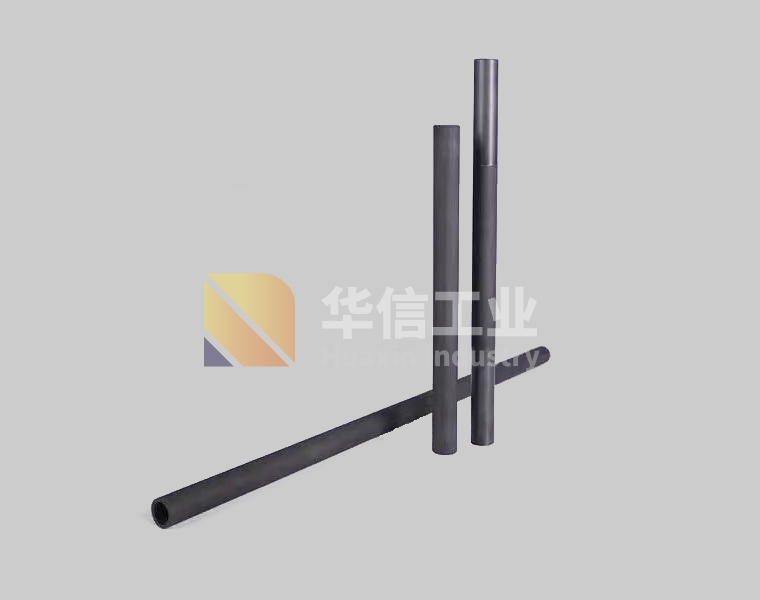

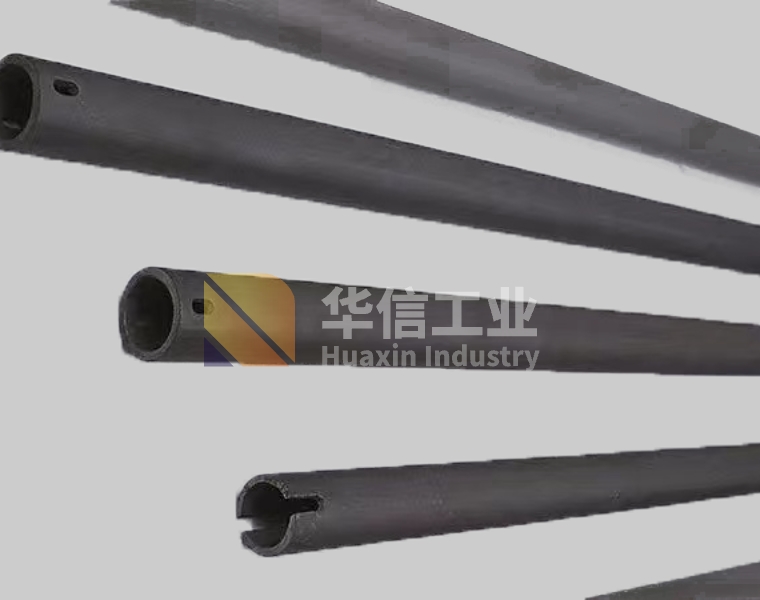

Related Products