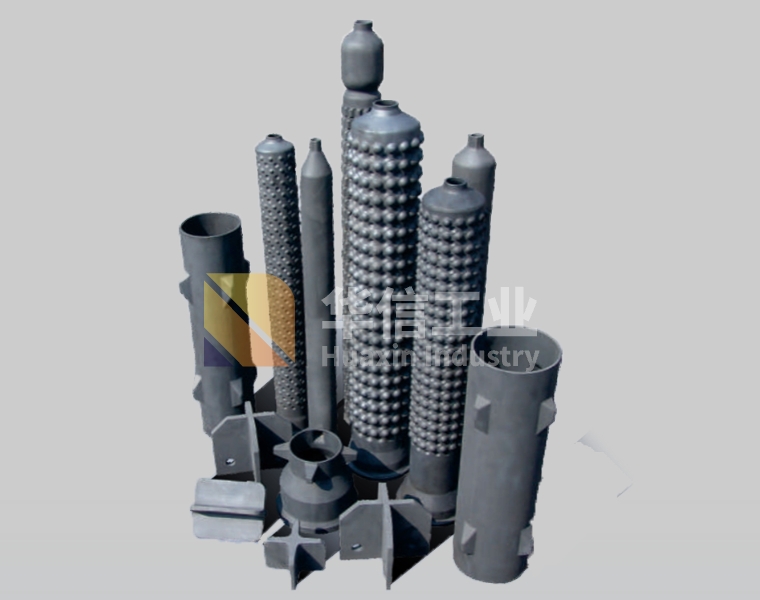

Silicon carbide porous ceramic rotating film

Silicon carbide ceramic membrane products are known as the most high-end products in the field of inorganic membranes in the 21st century. Both the support body and the film material are pure silicon carbide, sintered by recrystallization process at 2400 ℃, with a purity of > 99.5%

high hydrophilicity, contact Angle with water close to 0 °, very low filtration pressure loss;

High mechanical strength, withstand pressure > 10 kg, there is no organic film broken wire problem.

Extreme oxidation resistance, fluorine ion resistance, chlorine resistance - no limit concentration;

Extreme pH and temperature tolerance - no concentration of acid and base, temperature resistance of 800 ℃;

Strong oil pollution tolerance - unlimited concentration;

Superior chemical cleaning recovery ability - under extreme pollution conditions, continuous cleaning with high concentration of chemicals can restore the permeability as before.

Under the same conditions, the service life is more than 3 or 3 times that of other inorganic or organic membranes.

- Typical application

- Features and advantages

- Specification

-

Typical application

-

Features and advantages

Advantages of rotating filter membrane:

1. Extremely fast cross-flow speed (efficient cleaning film surface)

The cross-flow effect (tangential flow to clean the filter surface) is produced by the rotation of the filter disc rather than by conveying a large flow rate through the pump.

2. Low energy consumption (compared with traditional cross-flow technology)

Optimize internal flow to

3. Ceramic materials

Chemical and thermal stress resistance, high filtration flux, long service life, can be used to backwash or hot steam disinfection regeneration. -

Specification

Related Products