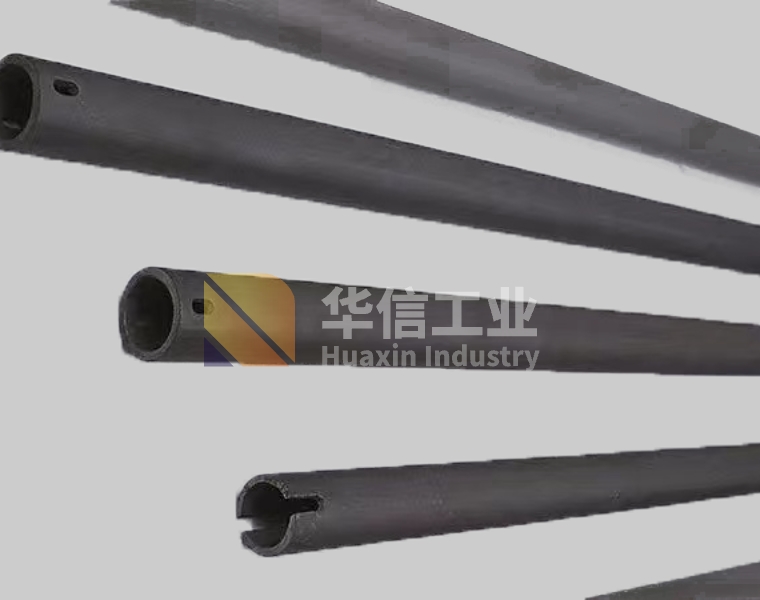

Tubesheet

Silicon carbide tubesheet is made of direct isostatic pressing and non-pressing sintering, and silicon carbide heat exchange tube is used to form silicon carbide tubesheet exchanger, mainly for high temperature and high pressure strong corrosion conditions.

The sealing method can be designed according to the design requirements, and the thread can be processed.

- Typical application

- Features and advantages

- Specification

-

Typical application

Tubular heat exchangers under high temperature and high pressure strong acid and alkali corrosion.

Applied industries: Fine chemical industry, pharmaceutical industry, environmental protection engineering. -

Features and advantages

Silicon carbide tubesheet size accuracy ±1.0mm, thickness ±0.1mm, can also be finished according to customer requirements, higher precision.

Silicon carbide tubesheet has a comprehensive corrosion resistance, can be used in sulfuric acid, hydrochloric acid, sulfuric acid, hydrofluoric acid and a variety of mixed acids, life is much higher than graphite and metal materials.

Silicon carbide tubesheet are designed with step slots or threads and are compacted with corrosion resistant materials such as perflurane O-rings.

The hardness of silicon carbide tube plate is second only to diamond, and it can be used under various working conditions with particle erosion, and the life is more than 5 times higher than that of graphite head.

Silicon carbide tubesheet are manufactured for strict dimensional and surface fluorescent penetration inspection. -

Specification

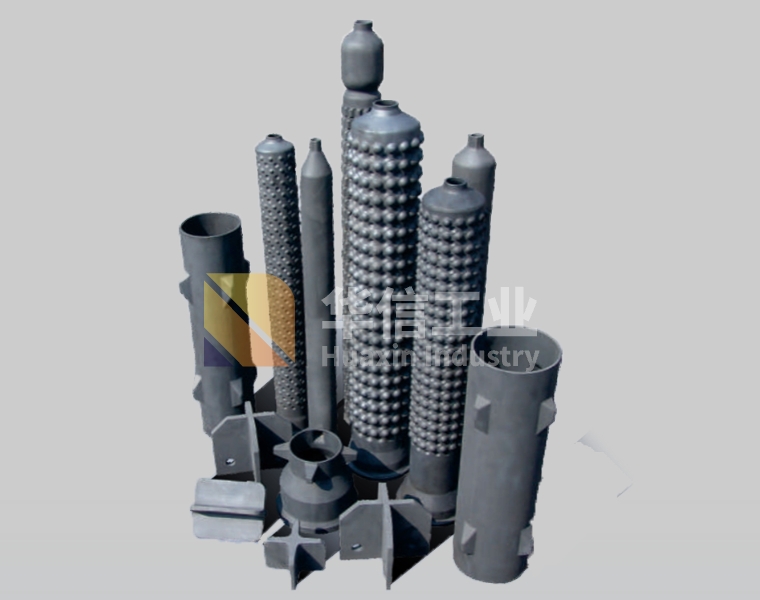

Related Products