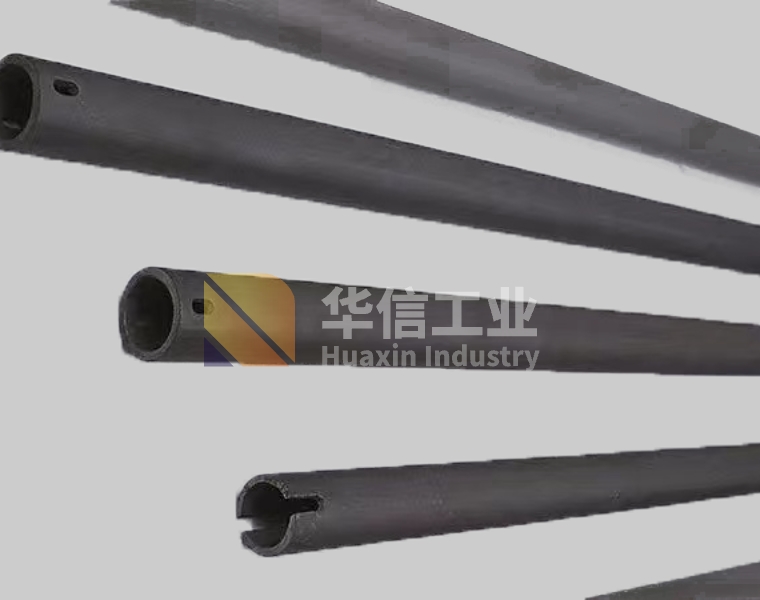

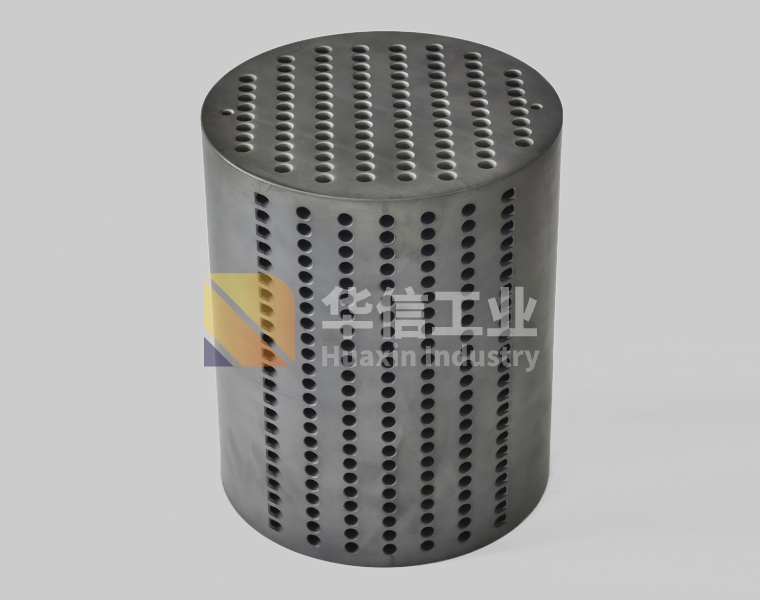

Heat exchange block hole

The silicon carbide heat exchange block hole is formed by direct isostatic pressing and non-pressing sintering, and the heat exchange of two media can be achieved through the wall of the vertical hole and the horizontal hole.

The aperture size can be designed according to the design requirements, the minimum aperture can be up to 6mm, the maximum hole wall thickness can be up to 2.5mm.

- Typical application

- Features and advantages

- Specification

-

Typical application

Block hole heat exchanger under strong acid and alkali corrosion.

Applied industries: Fine chemical industry, pharmaceutical industry, environmental protection engineering. -

Features and advantages

Silicon carbide heat exchange block hole size accuracy ±1.0mm, thickness ±0.1mm, can also be refined according to customer requirements, higher precision.

Silicon carbide heat transfer block hole thermal conductivity of 140W/m•K, with excellent heat transfer efficiency.

Silicon carbide heat exchange block hole has a comprehensive corrosion resistance, can be used in sulfuric acid, hydrochloric acid, sulfuric acid, hydrofluoric acid and a variety of mixed acids, life is much higher than graphite and metal materials.

Silicon carbide heat exchange block holes are designed with sealed waterlines and are tightly sealed by corrosion resistant materials.

Silicon carbide heat transfer block holes are manufactured for strict size, water pressure (40BAR), air pressure (15BAR) and surface fluorescence penetration inspection. -

Specification

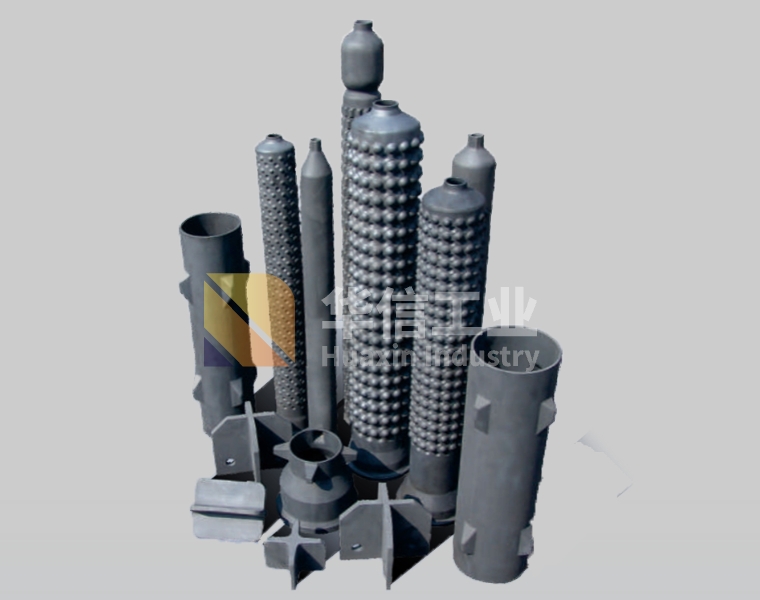

Related Products