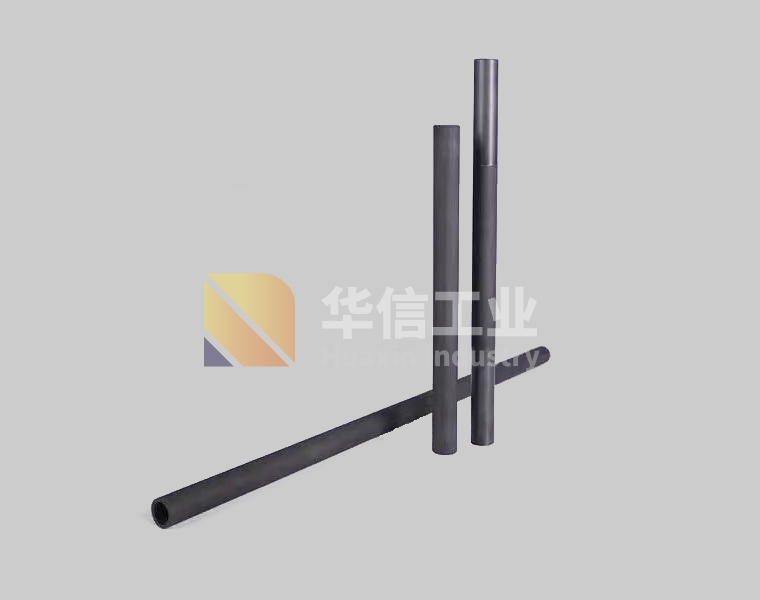

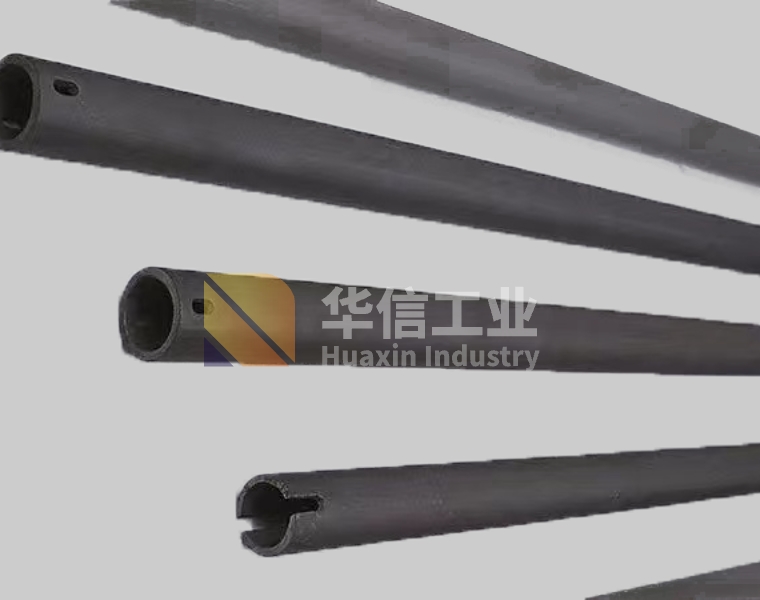

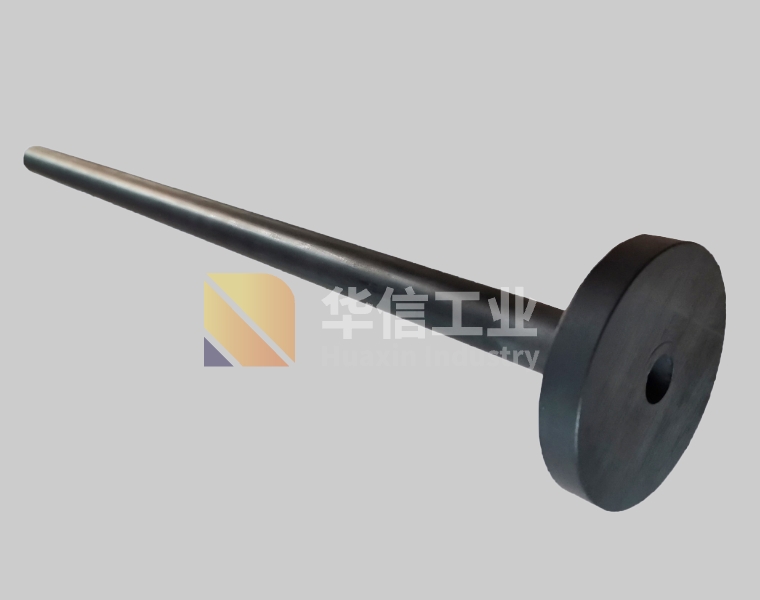

Protective casing

Silicon carbide protective casing is formed by isostatic pressing and sintered at high temperature. Due to the integral forming process, the blind end of the protective casing and the pipe are integrated. Either with or without a flange, according to the size, the flange can be formed with the casing as a whole, or the flange can be formed separately with the casing and then welded into a body at high temperature.

- Typical application

- Features and advantages

- Specification

-

Typical application

Silicon carbide protective casing is set outside the temperature measuring element or pre-installed on the equipment to resist the pressure and corrosion of the measured medium, commonly known as thermometer sleeve.

Silicon carbide protective casing for chemical pipelines, reactors, etc., can be easily installed and reliably sealed on test flanges. -

Features and advantages

Silicon carbide from room temperature to 1000℃, gas impermeability to 31MPa, can withstand high pressure.

Silicon carbide has a high purity (more than 99% SiC content), will not pollute the material.

Silicon carbide protective casing offer excellent corrosion and wear resistance even at high temperatures - without contaminating the material.

Due to high thermal conductivity and good thermal shock performance, the SIC protective casing also provides a rapid response to temperature changes. -

Specification

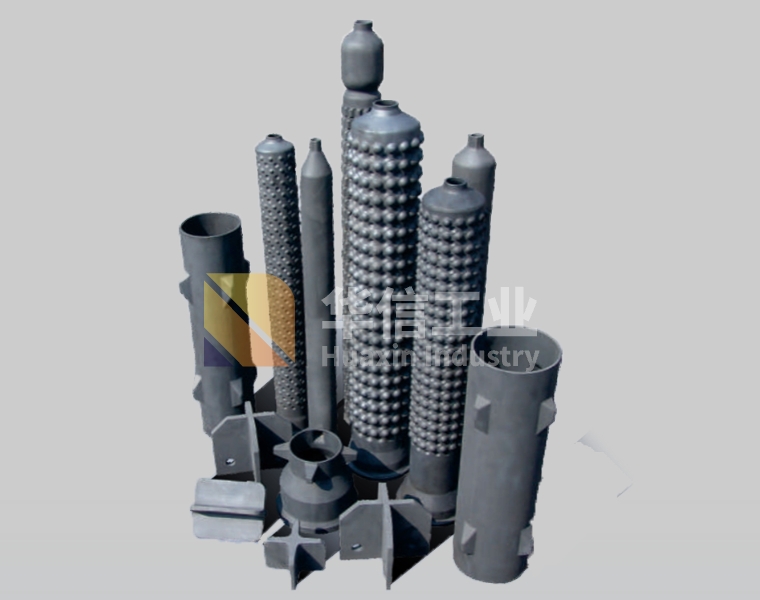

Related Products