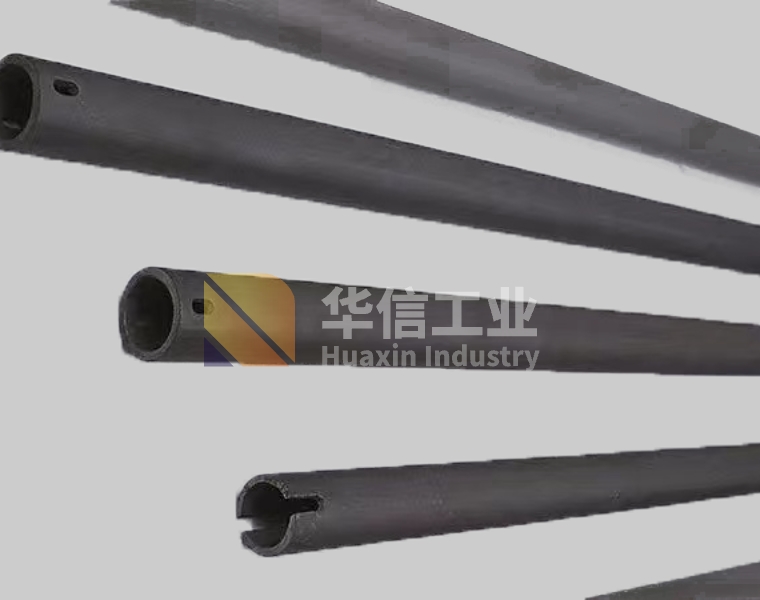

Sulfuric acid atomizer nozzle

The SIC sulfuric acid nozzle is made of direct isostatic pressing and non-pressing sintering, with excellent performance.

According to the requirements of multi-angle drilling, groove processing, internal and external diameters and end surfaces for finishing (including surface), can be entered

Line five-axis machining to meet the different design needs of users.

- Typical application

- Features and advantages

- Specification

-

Typical application

various concentrations of sulfuric acid atomizer, can also be used for other inorganic or organic acid atomization process.

Applied industries: waste acid burning furnace, waste incinerator, cracking furnace and other environmental protection engineering fields. -

Features and advantages

silicon carbide sulfuric acid atomizer nozzle can be drilled, groove processing, internal and external diameters and end faces for finishing (including curved surfaces), the maximum hole up to 0.5mm, processing accuracy up to 0.01mm.

silicon carbide sulfuric acid atomizer nozzle can be five-axis processing, to meet the multi-angle design.

silicon carbide sulfuric acid atomizer nozzle can carry out high precision polishing of the inner surface to meet different material requirements.

Silicon carbide ceramic nozzles are manufactured for strict density, size and surface fluorescence penetration detection.

silicon carbide ceramic density of 3.15g/cm3, Vickers hardness of more than 23GPa, high wear resistance.

The service life of silicon carbide ceramic nozzle can reach more than one year, which is more than 2 times higher than that of alloy nozzle (according to different media) -

Specification

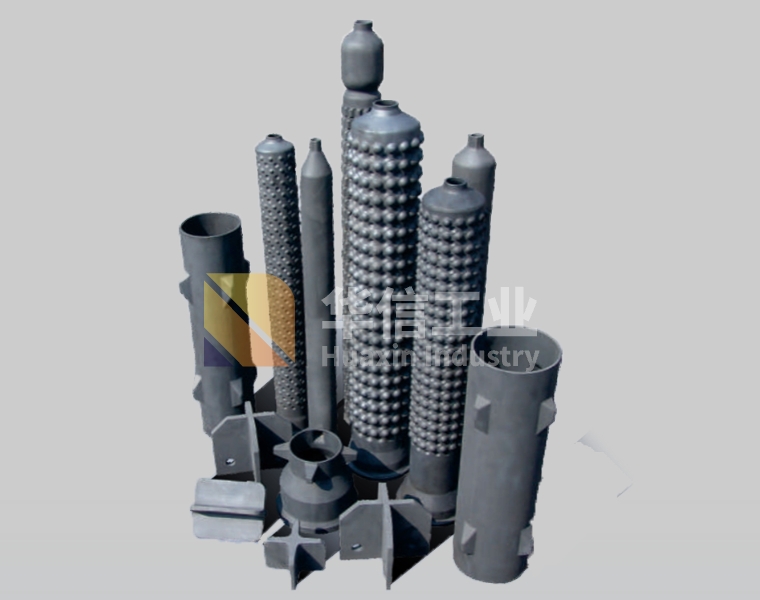

Related Products