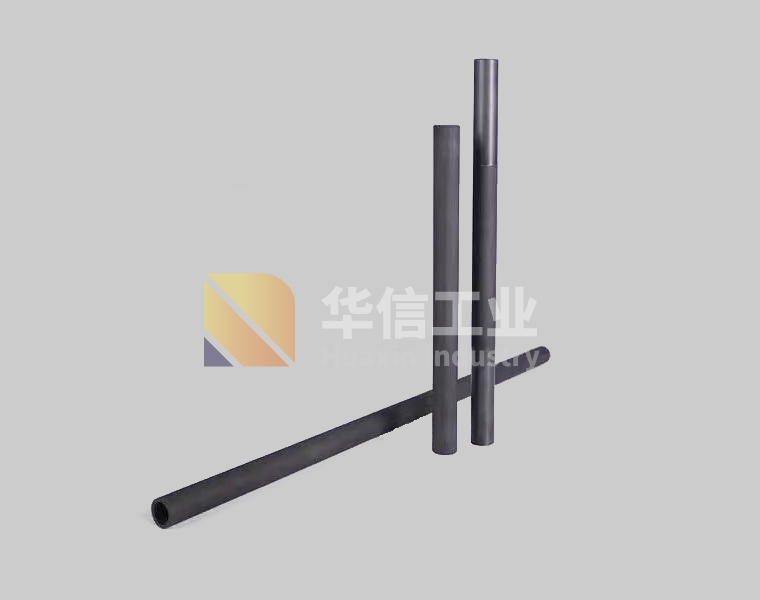

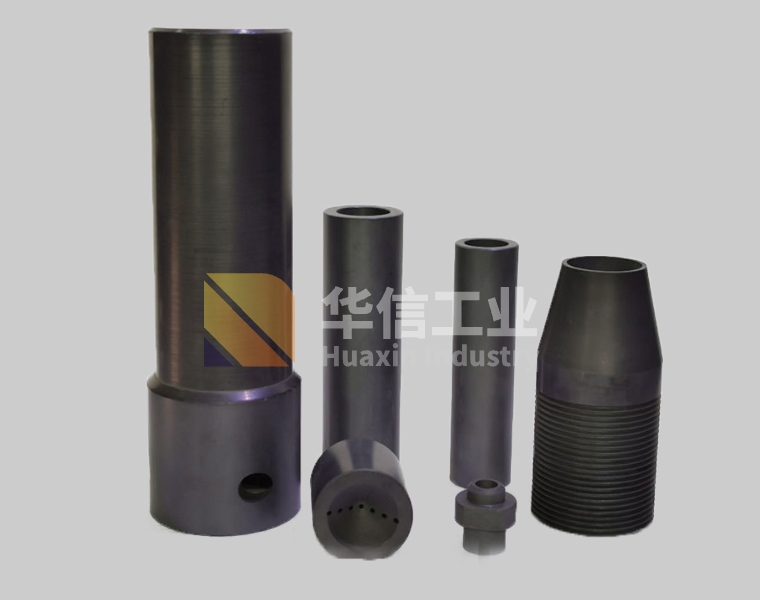

Sandblasting nozzles

The silicon carbide sandblasting nozzles is made of isostatic pressing and pressureless sintering, with excellent performance.

For drilling, groove processing, internal and external diameter and end surface finishing (including surface) to meet the customer's design requirements.

- Typical application

- Features and advantages

- Specification

-

Typical application

All kinds of dry powder, liquid sand blasting guns, etc

Applied industrial:metal pretreatment, mold treatment, strengthening, rust removal, finishing, etc.

-

Features and advantages

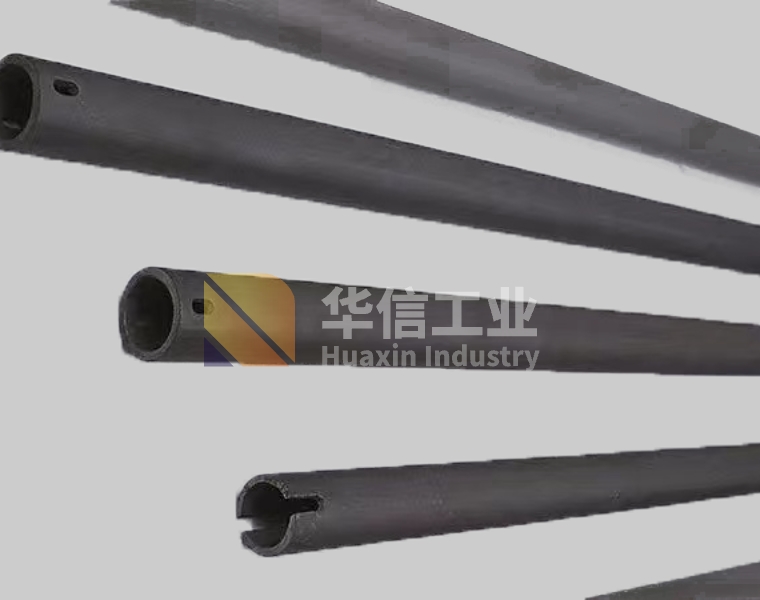

Silicon carbide sandblasting nozzles adopts dry bag CIP molding process, high density (> 3.15g/cm3), Vickers hardness of more than 23GPa, excellent wear resistance.

Silicon carbide sandblasting nozzles can be drilled, groove processing, internal and external diameter and end face machining (including curved surface), processing accuracy of 0.01mm.

Silicon carbide sandblasting nozzles are manufactured for strict density, size and surface fluorescence penetration detection.

The service life of silicon carbide sandblasting nozzles can reach 600-800 hours, more than twice the life of cemented carbide nozzle (according to different media) -

Specification

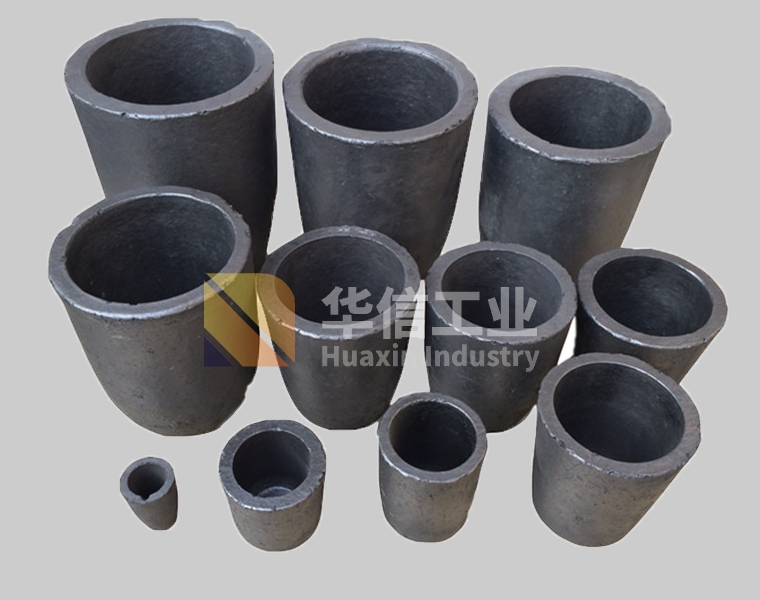

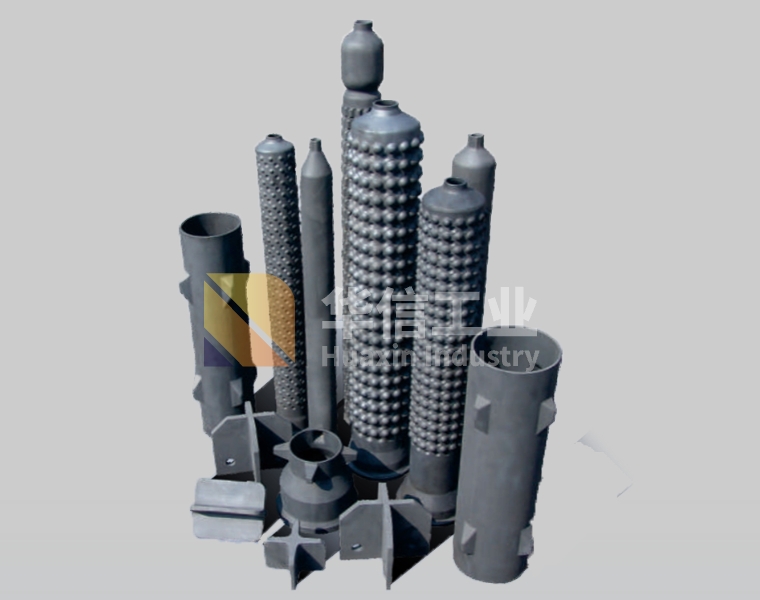

Related Products