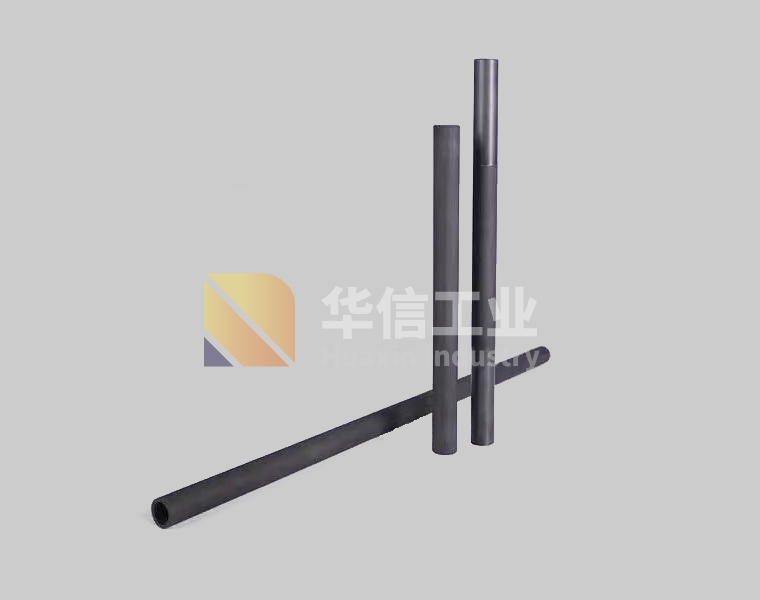

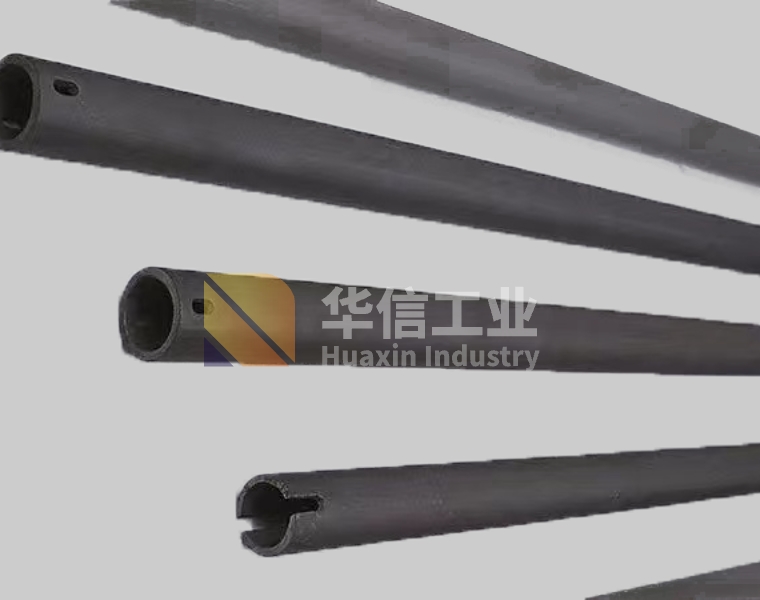

Plunger rod

The silicon carbide plunger rod is formed by dry bag isostatic pressing and sintering without pressure. According to design

To carry out multi-angle drilling, keyway processing, internal and external diameters and end faces for finishing, can be carried out five-axis processing to full meet the different design needs of users.

- Typical application

- Features and advantages

- Specification

-

Typical application

Plunger pumps with strong corrosion and particle erosion.

Applied industries: Fine chemical, pharmaceutical, medical, etc. -

Features and advantages

Silicon carbide plunger rod can be drilled, keyway machining, internal and external diameter and end face machining (including curved surfaces).

Silicon carbide plunger rod can provide rough billet, processing accuracy 0.1mm; It can also provide finished products, processing accuracy up to 0.001mm cylindrical, surface roughness Ra up to 20nm.

Silicon carbide plungers are manufactured for rigorous density, size, surface fluorescent penetration and surface microstructure inspection.

Silicon carbide plunger material density of 3.15g/cm3, Vickers hardness of more than 23GPa, high wear resistance.

Silicon carbide plunger material is TUV FDA certified to meet food-grade media delivery requirements. -

Specification

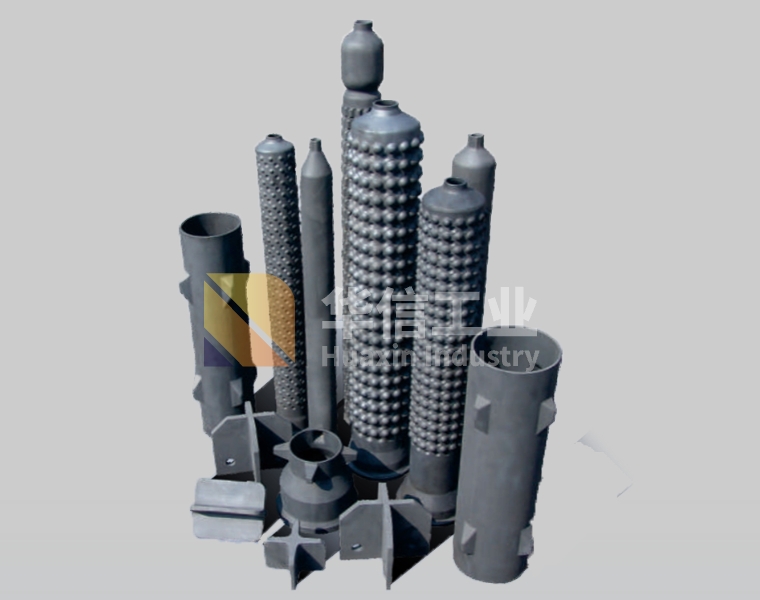

Related Products